Equipment Inspection Checklist in Salesforce (preventative maintenance)

Problem

Routine equipment maintenance is meant to verify operations and prevent sudden malfunctions. This can only be successful if the standard checklist and followup actions are performed. With conditional responsibilities varying from location to hardware, the likelihood of overlooked steps are increased, as are the chances of malfunctions that these routine audits are meant to avoid.

Solution

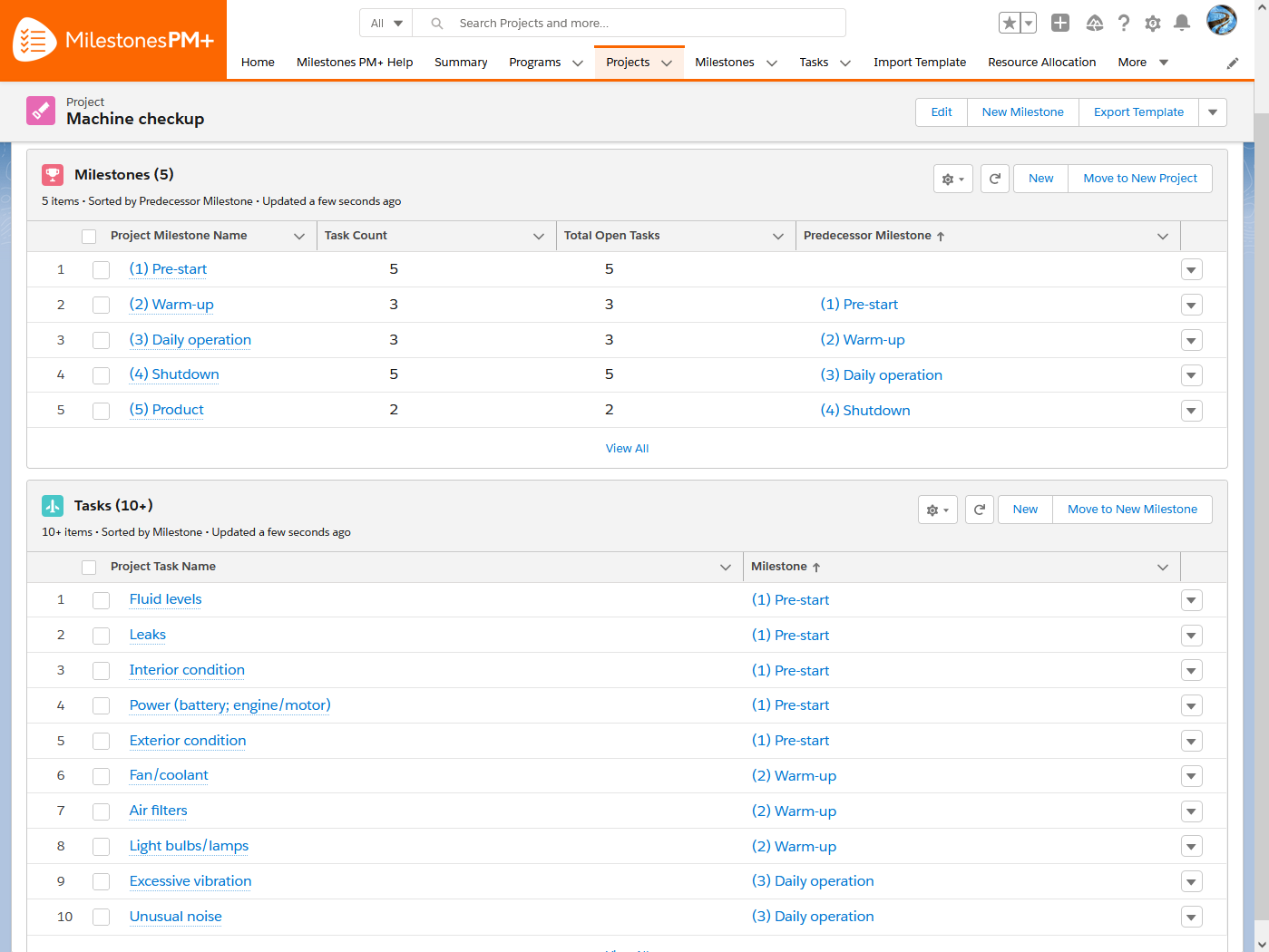

- A) A project with milestones for each machine and tasks for each list item.

- B-1) A project with milestones for each location, tasks for each machine, and to-dos for each list item.

- B-2) A program with projects for each location, milestones for each machine, and tasks for each list item.

With any of these project solutions, detailing the checklist reduces human error and guarantees visibility to all necessary actions.

Reduce errors and inaccuracies. By attaching specifications for the Resource to reference, reusable templates can confirm the correct machine is being inspected and ensure proper replacements are ordered. For example, a Project for Namebrand X4 printer can set limits on what ink cartridges and compatible parts are allowed to be associated based on brand, model, Salesforce data like record type, and other particulars.*

Visibility of maintenance costs. Project reports can show the efficiency of labor or mechanics over time to reveal: overspending, such as repair trends on end-of-life systems nearing replacement; underspending, such as more profitable systems requiring greater treatment; and improvement opportunities, such as skill gaps.*

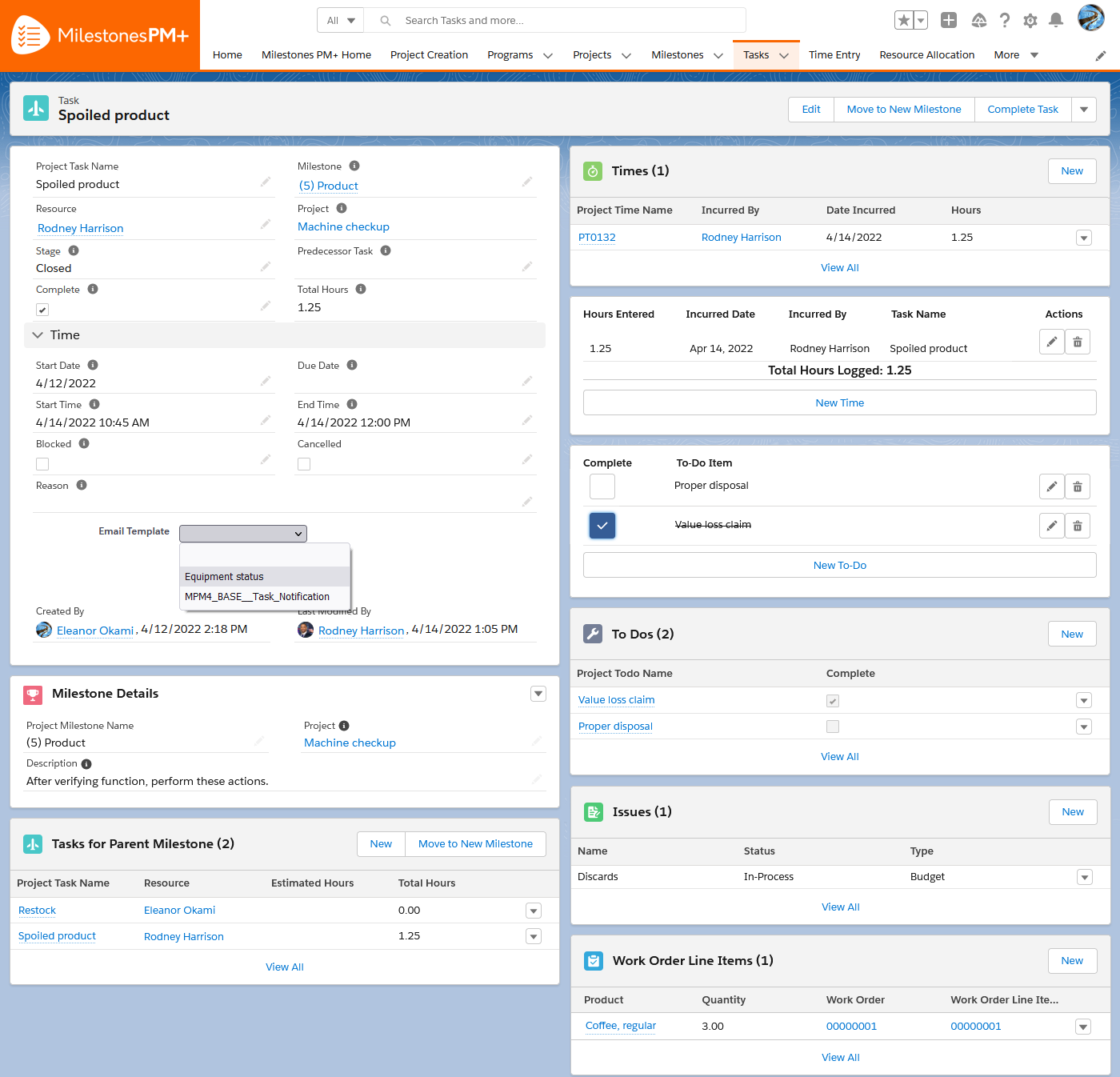

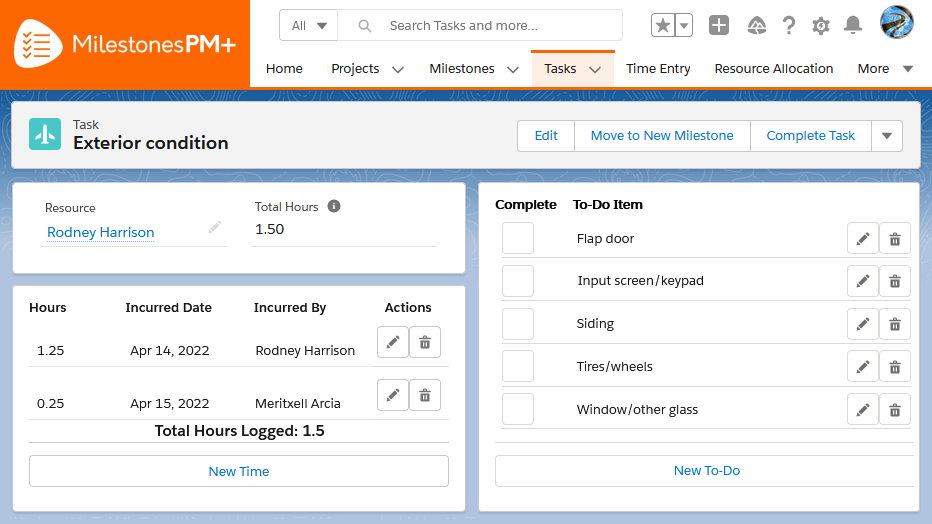

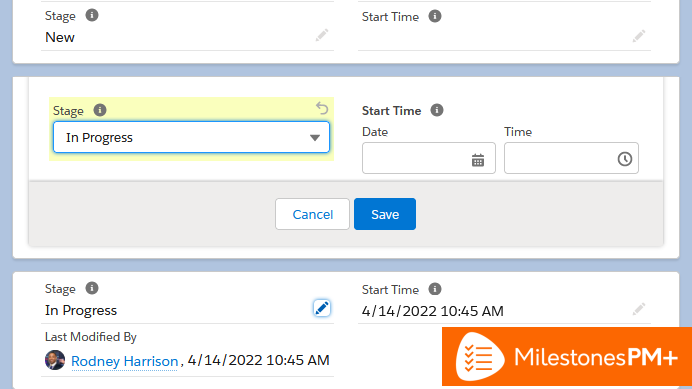

With Milestones PM+, Salesforce Products and Assets can be related to a Milestone or Task to confirm that the correct machine is being looked at, or to track what replacement parts are needed in a follow-up appointment. Issues can be logged explaining the required parts, and Risks can document possible future considerations such as updating slightly out-of-date software. Auto-create Time Entries from the Start/End Time fields for Time Grid submissions and custom reports.* Marking Tasks or Todos complete means every list item is addressed and improves the inspection quality, in turn ensuring consistent uptime and limiting unplanned failures.

Milestones PM+ is 100% Salesforce-native, meaning it integrates seamlessly with the Salesforce mobile app and Field Service on Service Cloud.

| Salesforce Health Check Projects for Admins | Milestones PM+ Use Case Library | Red Flags and Project Health in Salesforce |